Reducing costs and enhancing efficiency are critical aspects of the packaging lifecycle. As a professional provider of packaging technology solutions, controlling packaging costs is a key component of product management. Here, we explore common strategies for cost reduction in packaging, categorized into several key areas for reference.

1. Reducing Material Costs

One of the primary ways to cut costs in packaging is by altering the materials used. This can be achieved in several ways:

Material Substitution

- Switching to Cheaper Materials: Replacing expensive materials with more affordable alternatives can significantly reduce costs. For instance, substituting imported white cardboard with domestically produced white cardboard, silver cardboard with white cardboard, or white cardboard with gray-backed white cardboard.

Reducing Weight

- Down-Gauging Materials: Using thinner materials can also lower costs. For example, changing from 350g cardboard to 275g, or replacing a 250g duplex board with a 400g single layer.

2. Reducing Process Costs

Optimizing the processes involved in packaging production can lead to substantial cost savings:

Printing Techniques

- Switching from Hot Stamping to Printing: Replacing hot stamping with gold ink printing can be cost-effective. For example, changing hot gold stamping to cold foil stamping or simply printing with gold-colored ink.

- Replacing Laminating with Coating: Substituting lamination with varnishing can reduce costs. For instance, replacing matte lamination with matte varnish, or anti-scratch lamination with anti-scratch varnish.

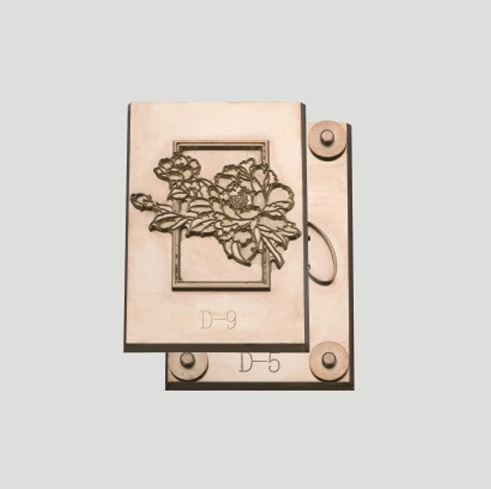

Consolidating Molds

- Combining Die-Cutting and Embossing: Using a single die that performs both die-cutting and embossing can save costs. This involves combining the embossing and cutting processes into one, thereby reducing the number of molds required.

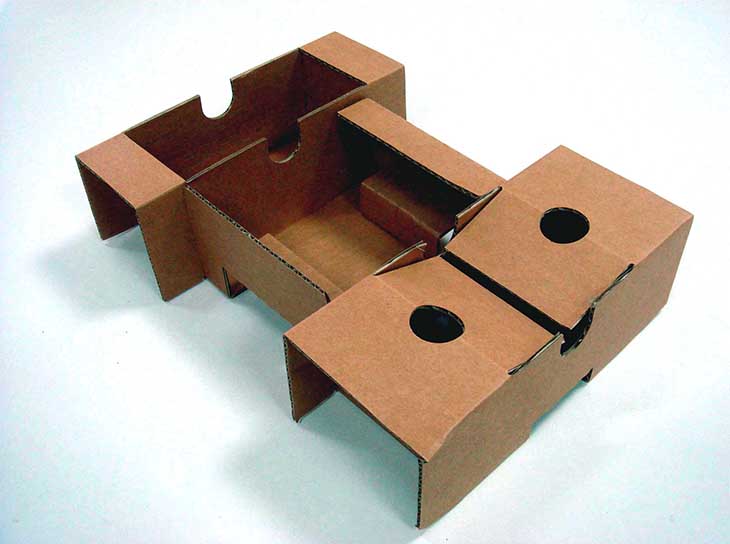

Structural Optimization

- Simplifying Packaging Structure: Streamlining the packaging structure can optimize its design for material efficiency and reduce transportation costs. Simplifying complex packaging designs to use less material can achieve this goal.

Implementing cost-reduction strategies in packaging structural design involves a multifaceted approach that includes material substitution, process optimization, material usage reduction, and automation. By focusing on these key areas, companies can achieve significant cost savings while maintaining the functionality and appeal of their packaging. As a professional provider of packaging solutions, we are committed to helping our clients optimize their packaging designs to enhance efficiency and reduce costs. Partner with us to create packaging that not only meets your needs but also stands out in the market.

Contact us today to learn more about our cost-reduction strategies in packaging design and how we can help you achieve your packaging goals efficiently and economically. Together, we can create innovative packaging solutions that make a difference.

Post time: Jun-22-2024