Card Box Corrugated Color Box Packaging Structure Design Printing Custom Manufacturer

Product Video

We have created a video tutorial on how to assemble double plug and airplane boxes. By watching this video, you will learn the proper assembly techniques for these two types of boxes, ensuring that your products are perfectly packaged and protected.

There are many different box styles to meet your packaging needs.

Card Box Corrugated Color Box Packaging Structure Design Printing Custom Manufacturer

Straight Tuck End Box

Both the top and bottom have tuck ends on the same ends of the box. Ideal if products can be inserted on either side of the box.

Reverse Tuck End Box

Both the top and bottom have tuck ends except on reverse ends on the box. Most popular choice by brands.

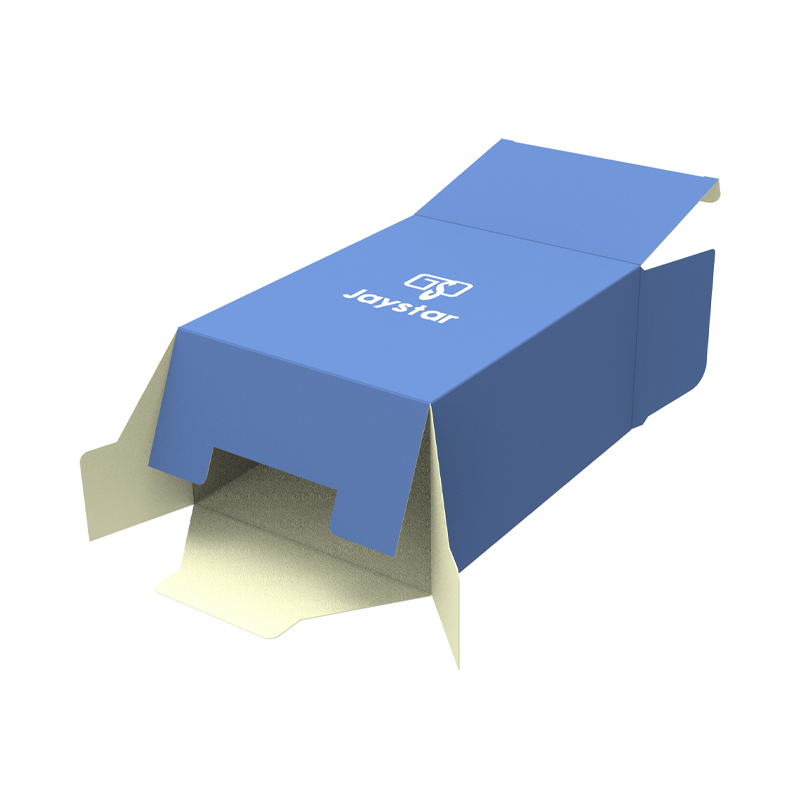

Snap Lock Bottom Box

Includes a tuck top and a bottom that can be folded and locked into place. Ideal for slightly heavier products.

Auto Lock Bottom Box

Includes a tuck top and a bottom that can be automatically snapped and locked into place. Ideal for heavier products.

Lightweight & sturdy

Folding cartons are lightweight compared to mailer boxes or rigid boxes, making them ideal for stacking or displaying in retail stores.

Technical Specs: Folding Carton Boxes

E-flute

Most commonly used option and has a flute thickness of 1.2-2mm.

B-flute

Ideal for large boxes and heavy items, with a flute thickness of 2.5-3mm.

White

Clay Coated News Back (CCNB) paper that's most ideal for printed corrugated solutions.

Brown Kraft

Unbleached brown paper that is ideal for only black or white print.

CMYK

CMYK is the most popular and cost effective color system used in print.

Pantone

For accurate brand colors to be printed and is more expensive than CMYK.

Varnish

An eco-friendly water-based coating but doesn't protect as well as lamination.

Lamination

A plastic coated layer that protects your designs from cracks and tears, but not eco-friendly.

Matte

Smooth and non-reflective, overall softer look.

Glossy

Shiny and reflective, more prone to fingerprints.

Mailer Box Ordering Process

A simple, 6-step process to getting custom printed mailer boxes.

Get a quote

Go to the platform and customize your mailer boxes to get a quote.

Purchase a sample (optional)

Get a sample of your mailer box to test size and quality before starting a bulk order.

Place your order

Choose your preferred shipping method and place your order on our platform.

Upload artwork

Add your artwork to the dieline template we'll create for you upon placing your order.

Start production

Once your artwork is approved, we'll start production, which typically takes 10-14 days.

Ship packaging

fter passing quality assurance, we'll ship your packaging to your specified location(s).